Basic concepts of control system

Before beginning with the concept of the control system, let’s first discuss about the system.

System

A system is an arrangement of different components that act together as a collective unit to perform a certain task. The physical system is defined as the collective action of physical objects in a system to perform an objective, for example a classroom. The classroom with benches, tables, fans, lights, blackboard, etc., collectively forms a physical system.

A kite is made up of sticks and paper, and the water in a lake is also a type of physical system.

Control system

Control means to regulate or direct. Thus, a control system is the interconnection of various physical elements connected in a way to regulate or direct itself or the other system.

Let’s consider a best example used in our day-to-day life, Air conditioner.

It takes the user’s input via remote, processes the instructions, and delivers the air to the respective room. The temperature control devices present in the air conditioner maintains the temperature as per the user’s requirements. When the desired temperature reaches, air conditioner automatically switches off the compressor. As soon as the temperature starts varying, it again switches on the compressor. The settings can be done manually via remote.

Air conditioner has three controls, temperature control, humidistat, and airstats. The temperature controls the temperature, the humidistat controls the relative humidity, and airstats controls the airflow inside the room.

So, we can conclude that a control system is an interconnection of the physical components to provide the desired function with some controlling action.

Now, let’s discuss some essential terms that will be helpful further in the tutorial.

Plant

The portion of the system that is to be controlled or regulated is known as plant of the process. In a control system, it is often referred to a transfer function, which specifies the relationship between the input and output of the system without feedback. It means that plant can be anything that has an input and provides the output.

The plant can have one or more output and inputs. The sensors are used to measure the plant’s output, while actuators drive the plants inputs.

The diagram of the plant is shown below:

The input variable in a system is generally called reference input and the output is called as the controller output.

Controller

The controller is the element of the system. It can also lie external to the system. The function of the controller is to control the plant or process. Every system accepts an input and defines the output after analyzing the nature of the input. The controller in the control system is a mechanism that reduces the difference between the actual value and desired value of the system. Here, the actual value signifies the real value, while desired value is the set-point or target value.

Input

It is a signal from the external energy source applied to the control system to produce the desired output.

Or

It is the desired action that is capable of producing any response in a system.

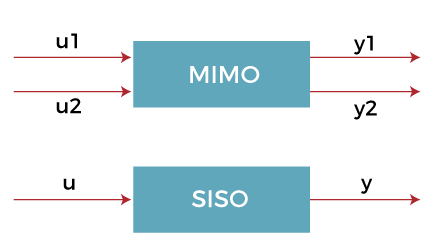

The common types of input used in the control system are SISO (Single Input Single Output) and MIMO (Multiple Input and Multiple Output). SISO means that the system produces single output for the single input, while MIMO produces multiple outputs for the multiple inputs. It is shown below:

The reference input in a control system is also known as the set-point, the desired value. It acts as the basis for error-controlled regulation using negative feedback for error control.

Output

It is an actual response of the applied input signal from the control system. The inputs are excited into the system and the outputs are the processed results of that inputs. The outputs are the results of either a small part of the process or the entire process.

Disturbances

Disturbances are a type of signal which adversely affects the output value of the control system. The disturbances can be internal or external. The internal disturbances that arise in the system itself and the external disturbances are generated outside the system. Such disturbances act as an extra input to the system and the normal input and further affect the system’s output.

Terminology of the control system

The terminologies of the control system are categorized as:

- Automatic control system

- Manual control system

- Linear control system

- Time-variant control system

- Time-invariant control system

Automatic control system

An automated control system without any human intervention is known as an automatic control system, such as an auto-pilot control system. It is a type of dynamic system in which differential equations generally describe processes. Other examples of the automatic control system are refrigerators, automatic ticket machines, etc.

With the help of feedback, the closed-loop system allows the system to correct the disturbances in the output, which makes the system an automatic control system.

Manual control system

A control system that is regulated with human intervention is known as a manual control system. It defines the manual controls that a human outside the system performs. Examples include sign-off documents and bank reconciliation. The primary function of manual control is to interfere or modify the process.

The Control system can either be automatic or manual, or both. Automatic controls are required when the system involves large transactions of similar nature. The manual controls are based on the required judgment.

Linear control system

As the name implies, it describes the linear relationship between the input and output. Or

A system in which the input and output relationship is described by the linear differential equation is known as linear system. Such systems also follow the superposition principle.

Time-variant control system

A system in which the input and output relationship is described by the differential equation with variable coefficient is known as a time-variant system.

Time-invariant control system

A system in which the input and output relationship is described by the differential equation with constant coefficient is known as a time-invariant system.

Negative feedback

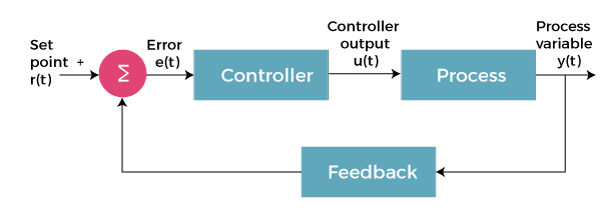

The block diagram of a closed loop system is shown below:

When the input is excited to the controller, it produces an actuating signal which controls the plant. The output, in such a case, adjusts automatically till the desired response is achieved. The feedback helps the system to correct the changes in the output and remove errors from it. Hence, a closed-loop system is also called an automatic closed-loop system.

We all are familiar with the feedback path in the control system. The feedback path helps in analyzing the error. The transfer function best describes the relationship between the input and output and thus helps in analyzing the error through the feedback.

Basic concepts of a control system

A control system defines the interconnection between various components. The individual components of a system can be electrical, hydraulic, mechanical, thermal, or chemical in nature. A well designed control system tends to produce the best response for the complete system. It can also handle the external, internal, and time-dependent disturbances effectively. The basic concepts of a control system are:

- To minimize the error

- To minimize the time-response

The lesser the error between the actual value and the desired value, the better the system’s response will be. It is because no system wants any error in between. The minimum time response of the system helps to load changes in the system.

Example

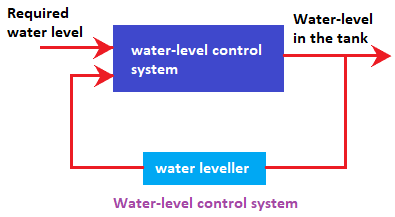

Let’s consider an example of water-level control system in a tank. When the pump in switched ON it allows the water to flow into the tank. Once the tank is filled up to the desired level, the pump will switch OFF.

The block diagram of the water-level control system is shown below:

Some people use a random method that indicates the filled tank and manually switches the ON and OFF button. But, in the industries and workplaces where there are many tanks and huge systems, the process works automatically. The sensors provide signals to the system.

Working

The water-level sensor gives the signal to the system that notifies the liquid level present in the water tank. The system compares that level with the desired water level. The system further provides the appropriate response to obtain the required water level in the tank. If the water level is low than the desired value, it switches ON the pump and water from the inlet flow into the tank. It is an example of a feedback control system where the sensor signals are given feedback from the output. It compares the actual output of the system with the required value and adjusts accordingly.