Chisel

A chisel is a type of cutting tool with a sharpened edge at the end. It is also used as a shaping tool. We can say that chisel is used to shape and cut wood, metals, and stone. It is a hand-held tool whose handle is made up of either wood or plastic. The chisel handle provides a better grip to hold the toll and perform the cutting and shaping operations. We can apply the force on the chisel either with mechanical power or by using the mallet.

A chisel is a handheld tool, which is supported by a wooden or metal handle. The preferred material for the chisel handle is wood because the metal can harm the chisel edge attached to it, our fingers, and our hands.

The cutting or shaping process is carried out by forcing the blade into the material using the hammer.

Chisel is used since the historic period. Today, chisels are available in various sizes and shapes according to their different uses.

Here, we will discuss the types of chisel, and the chisel process.

Types of chisel

Chisels are often used in woodworking and metalworking. The small chisel tools are used for fine details in the wood, while extensive tools are used to remove big wood sections from the wood piece. Both small and large tools are required for designing the wood piece.

Wood work chisels

The types of woodworking chisels are categorized as follows:

- Skew chisel

- Butt chisel

- Corner chisel

- Carving chisel

- Flooring chisel

- Framing chisel

- Mortise chisel

- Firmer chisel

- Paring chisel

- Drawer lock chisel

Skew chisel

It is a long flat chisel with a slanted end, as shown below:

The shortest point of the chisel edge is known as the heel, while the long point is known as the toe. It is generally used for trimming and finishing. The skew edge of the chisel is hand-controlled and can be used for detailed work.

Butt chisel

The butt chisel is a small version of the chisel, especially the firmer chisel. It is generally designed for butt hinge work. It is shown below:

It has a large size and is used to remove out large areas.

Corner chisel

The cutting edge of the corner chisel is L-shaped, which is used to clean corners, square holes. The angled of such type of the chisel is inclined at 90 degrees. It is also used to clean out the internal corners of the wood piece.

Carving chisel

Carving chisel is generally used for designing and sculpting. It is a good collection of various types of chisels used in the woodworking. It means that carving chisels has multiple functions, such as parting, cutting, paring, and skew.

It is shown below:

Flooring chisel

As the name implies, flooring chisels are used for the flooring purposes, such as cutting and removing flooring materials. The Flooring chisel is longer than other types of chisel. It is also suitable for tongue and grove flooring.

The flooring chisel is shown below:

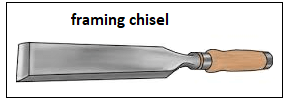

Framing chisel

The framing chisel is similar to the butt chisel but has a long and flexible blade. It is shown below:

A framing chisel is used for carving and wood frame construction.

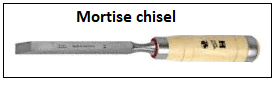

Mortise chisel

Mortise chisel has tapered ends, deep and straight cutting edge, and a rigid blade. Mortise means a hole with the corresponding projection. It is specially designed for chopping the mortise. It can be directly used to lever out the waste material from the workpiece. Other chisels do not have the thickness that can make them easily lever out the material.

It is shown below:

Firmer chisel

The firmer chisel is heavier and stronger. It has a wider blade with a thick rectangular cross-section. It is one of the main chisels used in woodworking. The thicker and stronger blade can cut or remove larger parts of wood from the workpiece. It is shown below:

When the firmer chisel is hit with the mallet, it can easily from large and deep cuts into the workpiece due to its sharp and strong ends.

Paring chisel

The paring chisel is a long, flat, and thin chisel used to remove thin layers of the wood. The ends of the chisel are taping at one side. It has a sharp cutting edge than gives clean cuts. It is shown below:

Metal work chisels

Metal work chisels are used to cut and shape metals. The chisels used in the metal work are categorized as cold chisels and hot chisels.

Cold chisels

Cold chisels are used to cut hard metals and remove waste from the metals surface. The cold chisel is used when other mechanical tools cannot complete the work. It has less acute angle shape at the end as compared to woodworking chisels.

The cold chisel term came when the blacksmiths uses the cold chisel to cut the metal. It comes in variety of sizes. Some cold chisels are tapped with a light hammer, while some are tapped with a long and heavy hammer.

Cold chisels are further categorized as:

- Flat chisels

- Diamond point chisel

- Cross cut chisel

- Round nose chisels

Flat chisels

It is a flat and tempered flat chisel. It is used to cut thick metal sheets when shear or other tools cannot cut. A flat chisel is generally made up of hard steel to maintain its flat finished surface easily. It is shown below:

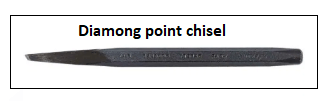

Diamond point chisel

It has a sharp point and is used to clean out difficult corners or places. It is also used to pull out the center punch marks that mistakenly occur during the drilling process.

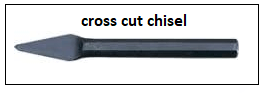

Cross cut chisel

It is also a chisel with pointed end. It is also known as ripping chisel and is used to cut wood, slots, and groves, as shown below:

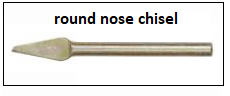

Round nose chisels

As the name implies, the round nose chisel is used to cutting the semi-circular grooves for oil ways in bearings, as shown below:

Hot chisels

The hot chisel is used to cut the hot metal. The metal is first heated in the forge until it turns red. The red metal is known as hot metal. The metal is burnt at a temperature suitable for cutting and shaping. The metal to be cut or shape is placed over the chisel and hit with a hammer. After that, it is picked or carried using a pair of tongs. The hot metal work piece is further dipped in the water for cooling.

But, what is the main difference between the cold chisel and the hot chisel? The cold chisel is hard or tempered because the metal being cut or shaped by it is hard. In the case of a hot chisel, the metal being cut is generally soft. Hence, the hot chisels are not as hard and tempered as compared to cold chisels.

Other types

The other types of chisel are categorized as stone chisels, masonry chisel, and gouge.

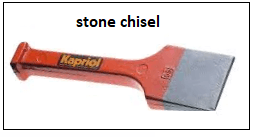

Stone chisels

As the name implies, stone chisels are used to cut the stones. It is also used to cut the bricks and the concrete slabs. The sculptors commonly use a spoon chisel (in the shape of a spoon). A force is applied to the chisel with the help of a hammer. A strong force requires a big hammer, while a light hammer is used to apply a light force on the workpiece. A type of stone chisel is shown below:

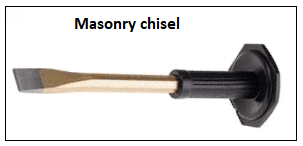

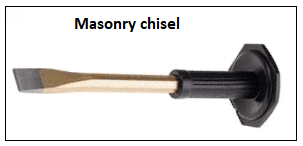

Masonry chisels

Masonry is a type of heavy chisel, which is used to break the workpieces. It is a dull chisel that is not meant to cut the workpiece. The weight of the mounted hammer is around three pounds or more. A masonry chisel is mounted with a hammer on the top, as shown below:

It is further categorized as flat chisels, flexible chisels, point chisels, etc. A flexible chisel has flexible blade and is easy to handle. The point chisel has a sharp end and is generally used for carving.

Gouge

A gouge is similar to the chisel but has a curve end instead of a flat end. We can also say that gouge has an angled cross-section at the end. The blade is also attached to the handle made of wood or metal. The preferred material for the handle is wood because wood is safe for hands and fingers compared to the metal handle.

Gouge with angled blades are known as ‘V- gouges.’ According to the curves of the different blades, each gouge is specified with a sweep number on it. For example, the gouge with sweep number 1 is flat, while the gouge with sweep number 9 is in the shape of a semi-circle. Similarly, gouge with sweep number 11 is U-shaped.

Other shapes of the gouge blade include fishtail and spoon-bent. It is generally used in arts and woodwork. For example, Carving a violin and cutting art sheets.

Other shapes of the gouge blade includes fishtail and spoon-bent. It is generally used in arts and wood work. For example, Carving a violin and cutting art sheets.

Other shapes of the gouge blade includes fishtail and spoon-bent. It is generally used in arts and wood work. For example, Carving a violin and cutting art sheets.

Chisel process

Let’s discuss how cutting or shaping is performed on wood, stone, and metals with the help of chisel.

1. Cutting a stone

- At first, we need to arrange the materials required for cutting, i.e., chisel, electric grinder with a diamond cutting blade, hammer, safety gloves, goggles, face shield, and a hearing protection. The diamond is used as the cutting blade because of its hardness and durability.

- To cut a stone, we should consider the length and thickness of the stone we want to cut. Mark around the stone for easy and accurate cutting.

- Chisel along the marked line with a help of the diamond cutter. Hold the stone tightly for better finish. Remember to wear an eye protection before performing the cutting process.

- We can now use the grinding tool, carve tools, etc. for designing purpose. We need to also wear dust marks, face shield, and other safety wears.

Similarly, we can cut other tools like wood and metals. We can also create designs on it as per the requirements.

Shaping the wood

Shaping is a process to cut the wood into the desired shape. We need to chop a small amount of wood from the wood piece at every cut for shaping. Some machines automatically perform the process. Here, we will discuss some common steps to shape the wood using the chisel.

- At first, we need to arrange the materials required for cutting, i.e., a chisel, hammer, a wood piece, and some safety measures.

- Hold the piece with force, so that it might not get displaced during the process. In case of large pieces, we can wrap one end of the wood to a heavy handle.

- We should use a plastic handle for a chisel instead of a metal handle. It will create less damage to the chisel, our fingers, and hands.

- Using a hammer, create cuts (large or small) as per the required depth.

- Create vertical cuts on the wood and remove the waste at every cut.

- We can also use a wider chisel because it provides better stability and finish. It also saves our time. We should ensure that our chisel is quite sharp before cutting the extra wood.

- A drilling machine can be used to make holes or the required design. To ensure a symmetric curve, focus on movement and steady pressure.

- Similarly, we can achieve the desired shape by performing the above steps or as per the requirements.